Blogs

Displaying

-

of

35

Article

How One Small Design Choice Can Transform an Entire Estate

In complex mental health estates, transformation rarely comes from sweeping change. More often, it comes from a series of small, deliberate design decisions that quietly reshape how environments function over time. This is especially true when considering cam locks in mental health environments.One ...

In complex mental health estates, transformation rarely comes from sweeping change. More often, it comes from a series of small, deliberate design decisions that quietly reshape how environments function over time. This is especially true when considering cam locks in mental health environments.One of the most overlooked of these decisions is the specification of tamper resistant cam locks. Often treated as a minor hardware detail, cam locks sit at the intersection of safety, access, maintenance, and long-term risk management. When specified thoughtfully, a secure cam lock approach can help bring clarity and consistency across an entire estate. Where small specification decisions set the direction for the whole estate Standardisation does not begin at handover. It begins from the moment a component is named on a drawing or schedule.In mental health environments, loosely defined specifications such as “cam lock” or “lock equal and approved” can introduce unintended variation. Over time, that variation compounds across cam locks in mental health environments, resulting in inconsistent outcomes including:• Inconsistent ligature risk profiles• Multiple access arrangements for staff• Increased pressure on estates and maintenance teams• Difficulty maintaining consistent safety standards across sitesA single, clearly defined mental health cam lock specification helps prevent this drift. By identifying one approved secure cam lock or security cam locks solution, estates teams can set a repeatable standard that carries through new builds, refurbishments, and reactive replacements. The hidden influence of everyday hardware Cam locks appear on almost every mental health estate. IPS panels, cupboards, service risers, radiator covers, and secure enclosures all rely on them. As a result, cam locks in mental health environments are handled daily by staff and sit within reach of service users.Because they are so common, the impact of specifying the right secure cam locks is often underestimated. These components must perform reliably in high-use, high-risk settings. When security cam locks are purpose-designed for mental health environments, they support anti-ligature principles, resist manipulation, and maintain consistent performance over time. When they are not, poorly suited cam locks can quietly undermine otherwise well-considered designs. Standardisation without restriction There is a persistent belief that standardisation limits flexibility. In practice, the opposite is true when the right cam lock system is chosen.A single tamper resistant cam lock platform can be configured for different applications through variations in cam length and fixing method. This allows secure cam locks to be used across steel, timber, and composite substrates without introducing additional lock types. As a result, estates teams and specifiers can:• Apply one approved solution across multiple environments• Support both retrofit and new-build projects• Avoid introducing new cam locks or access methodsThis approach delivers flexibility at the design stage, while maintaining simplicity and control at the operational stage. Long-term impact on estates and facilities teams The benefits of thoughtful specification are rarely immediate, but they are long-lasting. Consistent use of cam locks, supported by a single secure cam lock standard, delivers practical benefits over time.Standardised security cam locks support simplified maintenance and spares management, faster fault resolution, reduced training requirements, and clearer audit and compliance processes. For estates and facilities teams managing large, evolving portfolios, these efficiencies reduce day-to-day friction and free up time for higher-value activity. Aligning capital projects with the existing estate One of the greatest challenges in healthcare estates is ensuring that new developments do not reintroduce legacy risks or inconsistencies.By treating cam locks in mental health environments as a standardised safety system rather than a commodity item, capital projects can align more effectively with existing estate strategies. Using the same secure cam lock approach across projects supports safer handovers, smoother occupation, and greater confidence that standards are being upheld across the organisation. Conclusion: turning insight into informed decisions True standardisation is not achieved through mandates alone. It is built through informed, repeatable design choices that stand up to real-world use.Specifying the right tamper resistant cam lock may seem like a small decision, but its influence reaches far beyond the door or panel it secures. Across an entire estate, that single choice can reduce risk, simplify maintenance, and support safer outcomes through consistent use of cam locks and security cam locks.If you are reviewing specifications or planning upcoming works, the most effective way to build confidence is to assess solutions in practice.Request a free sample of Contour Secure’s tamper resistant secure cam lock and see how one small design choice can support safer, more consistent outcomes across your projects and estate. 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk

24 February 2026

Simplifying Access, Maintenance, and Risk Through Better Specification

In NHS mental health environments, specification decisions are rarely just technical. They sit at the intersection of safety, operational efficiency, compliance, and long-term estate management. Yet one area that is often underestimated is access control at the enclosure level. Cam locks may be ...

In NHS mental health environments, specification decisions are rarely just technical. They sit at the intersection of safety, operational efficiency, compliance, and long-term estate management. Yet one area that is often underestimated is access control at the enclosure level. Cam locks may be small components, but the consequences of how cam locks are specified can ripple across an entire estate, particularly in cam locks in mental health environments.For estates and facilities teams managing multiple sites, varied building ages, and constant adaptation, standardisation is not about removing choice. It is about reducing unnecessary complexity while strengthening risk control through a consistent approach to cam locks and secure cam lock selection. The hidden cost of inconsistent access solutions Over time, many mental health estates accumulate a wide mix of security cam locks. Different suppliers, different key types, different fixing methods, and different risk profiles all contribute to growing variation. Often this happens gradually, driven by project-by-project decisions rather than a coordinated strategy for cam locks in mental health environments.The result is familiar to most estates teams. Maintenance becomes slower because staff need access to multiple keys and spares linked to different cam locks. Training becomes more complex as teams need to understand which security cam locks are suitable in which areas. Audits and compliance checks take longer because risk assessments tied to cam locks are harder to evidence consistently.None of these issues are dramatic in isolation, but together they consume time, increase operational risk, and place additional pressure on already stretched teams. Why standardisation matters in mental health environments In mental health settings, access control is not just about preventing unauthorised entry. It is about designing out opportunity for harm, reducing tampering, and ensuring that only approved staff can access critical areas safely. This is why cam locks in mental health environments require more careful consideration than generic applications.Specifying a single, approved approach to secure cam lock use helps bring clarity. When tamper resistant cam locks and security cam locks are used consistently across enclosures, teams gain confidence that the same level of risk control is being applied whether a cam lock is fitted to a radiator cover, an IPS panel, or an electrical cabinet.This consistency supports safer environments for patients while also making life easier for the people responsible for maintaining cam locks day to day. Standardisation does not mean uniformity A common concern among specifiers is that standardisation removes flexibility. In practice, the opposite is often true. A well-designed mental health cam lock system allows cam locks to be used across materials, door thicknesses, and enclosure types without introducing new lock formats or new risks.Modern security cam locks can be specified to work across steel, timber, and composite panels, and across both retrofit and new-build projects. This allows capital projects and estates teams to respond to architectural and clinical requirements while still maintaining a consistent secure cam lock standard across the estate.The key difference is that flexibility is built into the cam lock system, not created by adding more lock types. Maintenance, access, and long-term efficiency From an estates perspective, the real value of better specification is often felt over time. Standardised cam locks and a single secure cam lock approach simplify spares management, reduce call-out times, and make fault resolution faster. Staff training becomes more straightforward because there is less variation in security cam locks to manage.Just as importantly, audits and compliance reviews become clearer. When one approved cam lock solution is used consistently, it is easier to demonstrate that access risks associated with cam locks in mental health environments have been considered and controlled across the estate.These efficiencies may not be immediately visible at handover, but they accumulate year after year. Better specification starts with small decisions Specifying for standardisation does not require a full redesign of an estate. It often starts with recognising that small components, like cam locks, play an outsized role in safety and operational performance.By taking a more strategic approach to specifying secure cam lock and security cam locks, estates and facilities teams can simplify access, reduce maintenance burden, and strengthen risk management without compromising clinical needs or design intent. Conclusion: see the difference for yourself Thoughtful specification is easiest when you can evaluate solutions first-hand. If you are reviewing access strategies across mental health environments, seeing how a secure cam lock performs in real-world conditions can make the decision clearer.To support that process, we offer a free sample of our tamper resistant cam lock, allowing you to assess its suitability for your estate before making any specification decisions. 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk

17 February 2026

Building a Safer Future: How Standardisation Supports Long-term Estate Resilience

In healthcare estates, every investment should deliver long-term value. For NHS Estates and Facilities teams managing safety-critical environments, that means implementing systems that are durable, maintainable, and adaptable as standards evolve. Contour Secure’s Standardisation Programme helps ...

In healthcare estates, every investment should deliver long-term value. For NHS Estates and Facilities teams managing safety-critical environments, that means implementing systems that are durable, maintainable, and adaptable as standards evolve. Contour Secure’s Standardisation Programme helps achieve exactly that. By unifying safety-critical enclosures under one tamper-resistant locking system, estates not only improve safety today, but they also build resilience for tomorrow. Why Resilience Matters Mental health environments are dynamic spaces that must adapt to changing patient needs, regulatory updates, and operational pressures. Over time, these changes can expose weaknesses in estate design, particularly when multiple locking systems are in use. Legacy fittings may not meet updated standards, replacement parts can become obsolete, and varying specifications make long-term maintenance inconsistent and costly. By standardising now, NHS Trusts can remove those future obstacles. A single locking platform ensures consistency, simplifies future upgrades, and maintains compliance as regulations evolve. Futureproofing Through Consistency Standardisation futureproofs healthcare estates by creating a unified, easily managed foundation. When every radiator guard, access panel, piece of furniture and fitted enclosure uses the same tamper-resistant lock, estates benefit from: Predictable maintenance: Standard components simplify repair and replacement, even years later. Continued compliance: One proven standard supports future HTM and CQC updates. Procurement efficiency: Bulk ordering and standard spares reduce costs and lead times. Sustainability: Fewer unique parts mean less waste and a smaller environmental footprint. A consistent standard makes estates more adaptable, allowing upgrades or expansions to integrate seamlessly with existing safety systems. Designed for Longevity Contour Secure’s tamper-resistant locking system is designed for durability and long-term use in healthcare settings. Each lock provides: Robust, anti-ligature performance Flush-fit, wipe-clean hygiene design Reliable operation under repeated use These qualities not only protect patients and staff but also reduce the frequency of maintenance interventions, saving time, resources, and cost over the lifetime of the estate. A Long-term Partnership Resilience is built through partnership. Contour Secure continues to support NHS Estates teams beyond installation, offering guidance on system maintenance, compliance documentation, and future estate planning. By embedding a standardised approach today, Trusts create an adaptable infrastructure that supports safety, efficiency, and innovation well into the future. Conclusion: Standardisation as a Strategy for the Future Standardisation isn’t just about solving today’s problems; it’s about preparing for tomorrows. By adopting Contour Secure’s tamper-resistant locking system, NHS Estates teams can build long-term resilience into their infrastructure, ensuring that their environments remain safe, compliant, and easy to manage as healthcare standards continue to evolve. Futureproof your estate with Contour Secure. Standardise your locking systems today and build a safer, more resilient environment for the years ahead. 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk

30 December 2025

From Audit to Implementation: How Contour Secure Supports Standardisation Across Estates

For many NHS Estates and Facilities teams, the idea of standardising safety systems across multiple sites can feel daunting. With busy live environments, legacy infrastructure, and ongoing maintenance demands, large-scale upgrades must be carefully planned and expertly executed. That’s why Contour ...

For many NHS Estates and Facilities teams, the idea of standardising safety systems across multiple sites can feel daunting. With busy live environments, legacy infrastructure, and ongoing maintenance demands, large-scale upgrades must be carefully planned and expertly executed. That’s why Contour Secure’s Standardisation Programme has been designed as a managed, step-by-step process. From initial audit to full implementation, our approach ensures that the transition to one tamper-resistant locking system is safe, efficient, and tailored to the unique needs of mental health environments. Step 1: The Estate Audit Every successful standardisation journey begins with understanding the current landscape.Our team starts with a comprehensive audit, identifying where legacy locks, mixed systems, or non-compliant fittings are currently in use. The audit process includes: Site inspections to review enclosures such as radiator covers, IPS panels, and fitted furniture. Documentation mapping to record existing lock types and key systems. Risk assessment to highlight safety, ligature, and hygiene concerns. This audit provides the foundation for a strategic upgrade plan, giving estates full visibility of their current position before any changes are made. Step 2: The Upgrade Plan Following the audit, Contour Secure develops a phased upgrade plan designed to minimise disruption and align with estate priorities. This includes: Detailed scheduling around operational needs and ward occupancy. Specification alignment to ensure new locks integrate seamlessly with existing enclosures. Procurement coordination to manage materials efficiently. The goal is a smooth transition from multiple lock types to one consistent, tamper-resistant standard, without affecting day-to-day operations. Step 3: Supply and Installation Implementation is carried out by experienced, accredited installation teams who understand the challenges of working in live mental health environments. All installations follow a strict safety and hygiene protocol to ensure patient welfare and minimal disruption. Each lock is fitted, tested, and documented in line with NHS standards, providing Estates teams with full traceability and confidence in compliance. Contour Secure’s tamper-resistant locking system is manufactured in the UK, with durable materials designed for long-term reliability in healthcare settings. Step 4: Ongoing Support and Documentation Our partnership doesn’t end at installation. Contour Secure provides post-project support that includes: Staff training on access procedures and maintenance. Comprehensive documentation to support CQC and HTM audits. Maintenance guidance to ensure continued safe performance. We understand that standardisation is an ongoing commitment. Our support helps ensure the system remains effective and compliant long after the initial rollout is complete. A Partnership Built for Healthcare Contour Secure has extensive experience working within mental health environments, understanding the sensitivities and operational demands these settings require. By acting as a collaborative partner, not just a supplier, we help Estates and Facilities teams achieve a safer, more consistent environment; one that reduces administrative strain and enhances patient safety. Conclusion: Streamline for Safety and Savings Standardisation doesn’t have to be complex. With the right partner, it becomes a structured, supported process that delivers lasting results. From the first audit to the final installation, Contour Secure works alongside NHS Estates teams to simplify, strengthen, and secure their environments through one proven, tamper-resistant locking standard. Partner with Contour Secure to deliver a safe, compliant, and consistent estate through our full Standardisation Programme. 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk

23 December 2025

Healthcare Locking Solutions: A Complete Guide to Safety, Hygiene, and Retrofit Options

Healthcare facilities face increasing pressure to deliver environments that are secure, hygienic, and cost-effective. From IPS panels in bathrooms to furniture in bedrooms and access hatches in corridors, locking systems are a small but critical component of this goal. Too often, locks are ...

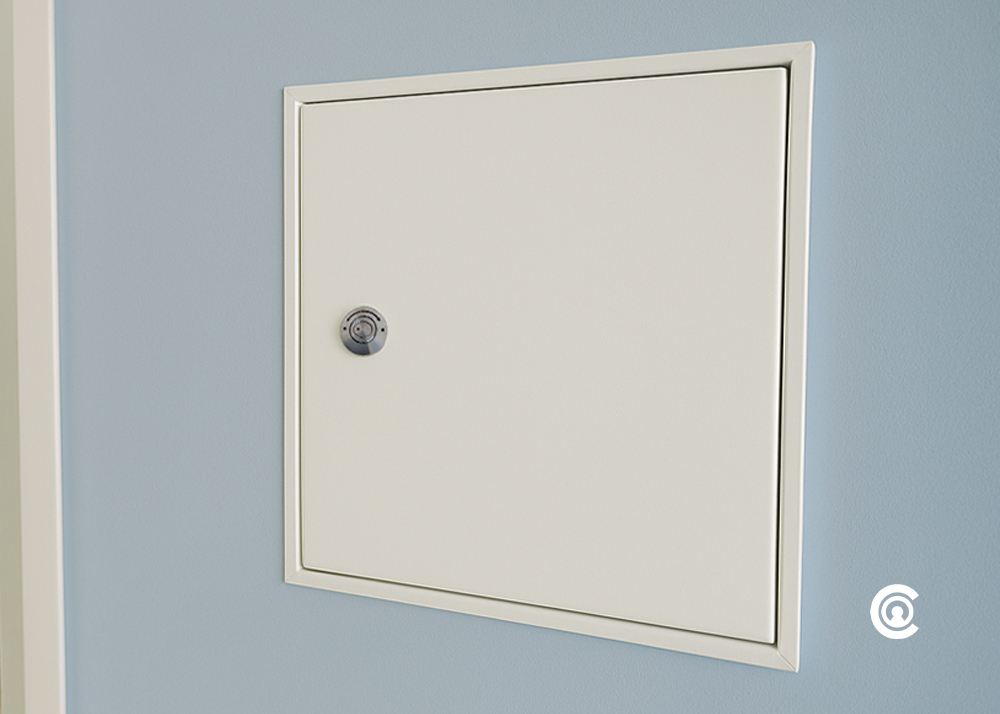

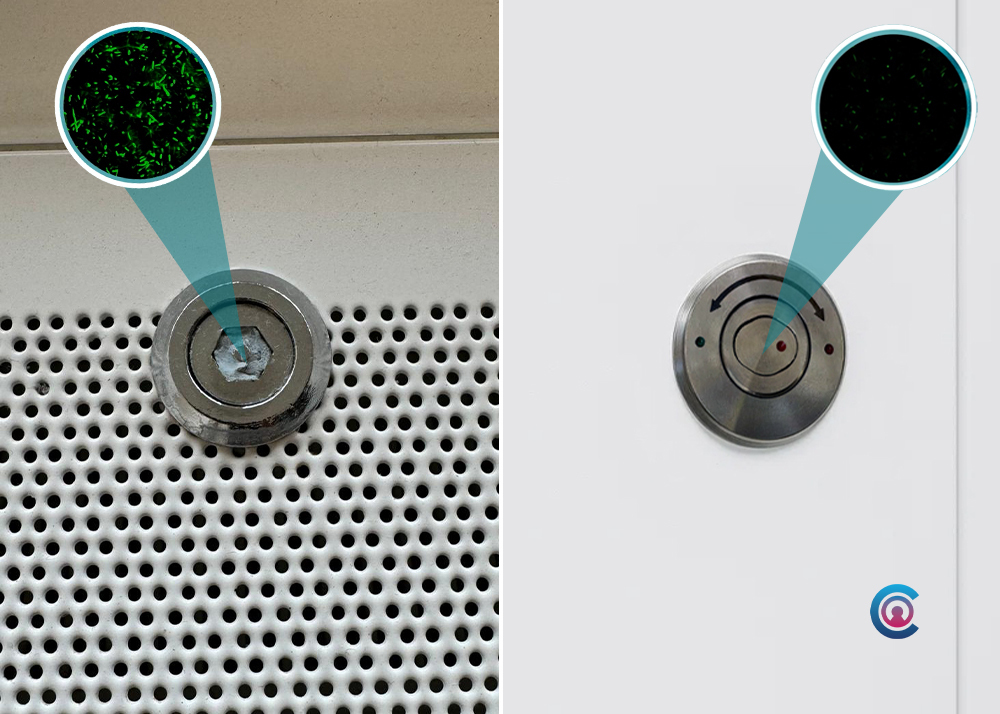

Healthcare facilities face increasing pressure to deliver environments that are secure, hygienic, and cost-effective. From IPS panels in bathrooms to furniture in bedrooms and access hatches in corridors, locking systems are a small but critical component of this goal. Too often, locks are overlooked. Yet they directly affect patient safety, infection control, operational efficiency, and long-term maintenance costs. This complete guide brings together the key considerations for healthcare estates, specifiers, and product manufacturers when it comes to cam locks. It explores the risks of outdated designs, the benefits of modern alternatives, and practical retrofit solutions that allow healthcare teams to upgrade without disruption. Why Locks Deserve More Attention in Healthcare When most people think about healthcare safety, they picture ward layouts, clinical equipment, or staff training, but locks are present across every part of an estate: IPS panels in bathrooms and clinical areas Access panels in corridors and service spaces Furniture in bedrooms, treatment rooms, and staff areas Storage units for medicines and equipment Each lock interacts with staff, patients, and cleaning teams daily. If these locks are outdated, they can become weak points that compromise safety and efficiency. The Safety Risks of Legacy Locks Legacy lock designs such as pin hex, crown, tri-head, and square-head inserts were never intended for the unique demands of healthcare. Their weaknesses include: Tampering: Easily opened with improvised tools. Ligature risks: Protruding faces and sharp edges create hazards in mental health settings. Mechanical weakness: Older locks may fail under repeated use, causing downtime and costly repairs. In healthcare environments, these risks can have serious consequences, from patients accessing dangerous services behind panels to repeated maintenance callouts that disrupt ward operations. The Hygiene Case: Why Flat-surfaced Locks Matter Infection control is a constant challenge across estates. Yet traditional locks often have recessed keyways and ridges that trap dirt and bacteria, undermining cleaning regimes. Flat-surfaced cam locks, by contrast, provide: Smooth, wipe-clean faces that integrate into infection control protocols. Faster cleaning times, reducing workload for estates and cleaning teams. Antimicrobial compatibility, allowing coatings to perform effectively. Visual consistency, supporting modern, therapeutic healthcare design. By standardising flat-surfaced locks across facilities, estates teams can strengthen infection control without adding complexity. Retrofitting for Resilience One of the most practical advantages of modern cam locks is their retrofittable design. Many can be fitted directly into the same footprint as standard locks, offering: Quick installation with minimal downtime. Cost savings compared to replacing entire panels or furniture units. Improved resilience with locks designed for tamper-resistance and hygiene. Extended asset life, helping budgets go further. Retrofitting ensures healthcare estates can raise safety standards immediately, without waiting for major refurbishment programmes. Where Locks Matter Most Locks are present in every corner of healthcare estates. Some of the highest-impact applications include: IPS Panels: Securing plumbing and mechanical services in bathrooms and clinical areas. Access Panels: Protecting electrical and mechanical services in corridors. Furniture Locks: Used on built-in storage or patient-area furniture, where low-profile and hygienic designs prevent ligature and infection risks. Ward Environments: Bedrooms, bathrooms, and treatment areas where consistency of lock design helps staff operate efficiently while keeping spaces secure. By recognising the variety of these applications, healthcare teams can apply a holistic approach to lock specification and upgrades. Raising the Bar for Healthcare Locking Standards The healthcare sector is evolving. Standards for safety, hygiene, and design have become more stringent, and locks must keep pace. Key design features in modern cam locks include: Three-point engagement mechanisms that increase tamper resistance. Compression rings that reduce rattle, improve strength, and deter manipulation. Low-profile faces that minimise ligature risks and support infection control. Visual lock indicators to help staff confirm locked/unlocked status immediately. These aren’t just incremental upgrades, they represent a step-change in how locks contribute to safety, hygiene, and resilience across healthcare estates. Small Details, Big Impact From IPS panels in bathrooms to furniture in bedrooms, locks may seem like a small detail in healthcare estates, but they have an outsized impact on safety, hygiene, and long-term costs. By adopting modern tamper-resistant, flat-surfaced cam locks, estates teams and manufacturers can reduce risks, support infection control, and extend asset life, all while keeping disruption and budgets under control. 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk🌐 Or visit: www.contoursecure.co.uk to request a sample or discuss how Secure cam locks can support your next healthcare project.

16 December 2025

The Hygiene Case for Flat-surfaced Locks in Healthcare Environments

Infection control is one of the highest priorities in healthcare environments. Estates managers, clinical leads, and product manufacturers are under constant pressure to deliver facilities that support cleanliness and patient safety. Yet one of the most overlooked contributors to infection risk is ...

Infection control is one of the highest priorities in healthcare environments. Estates managers, clinical leads, and product manufacturers are under constant pressure to deliver facilities that support cleanliness and patient safety. Yet one of the most overlooked contributors to infection risk is the humble lock. From IPS panels to furniture cupboards and access hatches, locks are touched multiple times a day by staff but rarely considered in infection control strategies. Traditional recessed locks create dirt traps that harbour bacteria and make thorough cleaning almost impossible. In contrast, flat-surfaced cam locks are designed to support modern hygiene standards, making them an essential upgrade for today’s healthcare estates. The Hidden Hygiene Risks of Traditional Locks Legacy lock designs (such as pin hex, crown, or square head) were not created with infection control in mind. Their recessed faces, deep grooves, and exposed ridges create surfaces where dirt and bacteria can accumulate unnoticed. These flaws lead to several risks: Inconsistent cleaning: Recessed keyways are difficult to disinfect effectively, meaning they are often overlooked. Infection control gaps: Dirt build-up undermines cleaning regimes and risks spreading pathogens. Visual clutter: Bulky lock designs can appear institutional and out of step with modern healthcare design. In environments where every surface must be easily wipe-clean, traditional locks represent a hidden weak point. Why Flat-surfaced Locks are Different Flat-surfaced cam locks are engineered to eliminate these hygiene pitfalls. Their smooth, flush faces remove ridges and recesses, making them easy to wipe down during routine cleaning. The benefits include: Improved infection control: Smooth surfaces prevent dirt traps, supporting high hygiene standards. Faster cleaning: Estates and cleaning teams can disinfect locks as quickly as other wipe-clean surfaces. Antimicrobial compatibility: Coatings are more effective on smooth faces, providing an additional layer of defence. Modern appearance: Sleek designs support a therapeutic, non-institutional look in patient-facing areas. More Than Just Hygiene: Safety and Usability Flat-surfaced locks don’t just address hygiene, they bring wider advantages for healthcare estates: Tamper resistance, reducing risks of unauthorised access to IPS panels or storage. Ligature resistance, with low-profile designs that minimise risks in mental health settings. Ease of retrofitting, allowing existing furniture, panels, and hatches to be upgraded without replacement. Clear engagement indicators, helping staff confirm locked/unlocked status immediately. Together, these benefits make flat-surfaced cam locks a small change with big impact across safety, hygiene, and efficiency. Supporting Whole Estate Hygiene Strategies Infection control is not just about wards and clinical spaces. Bathrooms, bedrooms, corridors, and treatment areas all contain locks on IPS panels, access hatches, and furniture. Without hygienic designs, these locks become weak points across entire estates. By specifying flat-surfaced locks consistently across facilities, estates managers can: Standardise cleaning routines. Reduce the risk of missed surfaces. Extend the lifespan of furniture and panels through easier maintenance. Consistency also simplifies training for estates and cleaning teams, ensuring every component supports the same infection control goals. Update Hygiene, Strengthen Safety Outdated locks with recessed designs can trap dirt and undermine infection control in healthcare environments. Flat-surfaced cam locks provide wipe-clean simplicity, improved hygiene, and added tamper resistance, all while fitting into standard lock footprints. It’s a small upgrade with significant benefits for patient safety and operational efficiency. 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk🌐 Or visit: www.contoursecure.co.uk to request a sample or discuss how flat-surfaced cam locks can support your infection control strategy.

11 December 2025

Fewer Keys, Lower Costs: The Operational Benefits of Standardising Locking Systems

Every NHS Estates and Facilities team faces the same challenge: maintaining safety and compliance within tight operational budgets. From reactive maintenance to key management, the practical realities of running a healthcare estate are complex and often made harder by one simple problem: ...

Every NHS Estates and Facilities team faces the same challenge: maintaining safety and compliance within tight operational budgets. From reactive maintenance to key management, the practical realities of running a healthcare estate are complex and often made harder by one simple problem: inconsistency. Across many mental health estates, years of upgrades and maintenance cycles have led to multiple lock types, varied key systems, and non-standard fittings. While this patchwork approach evolves naturally over time, it introduces hidden inefficiencies that cost more to manage in the long term. Contour Secure’s Standardisation Programme is designed to address those inefficiencies head-on, helping estates transition to one tamper-resistant locking system across all enclosures. The result? Fewer keys, faster maintenance, and lower lifetime costs, without compromising safety or compliance. The Cost of Complexity A mixed locking environment doesn’t just create confusion; it drains resources. Every unique lock type requires a separate key, maintenance routine, and set of spare parts. Over time, this leads to: Key proliferation: Dozens of key types circulating among estates teams, contractors, and maintenance staff. Increased training needs: Staff must understand multiple systems, each with its own access process. Higher maintenance costs: Stocking, repairing, and replacing varied lock types increases overhead. Greater downtime: Repairs take longer when components and keys differ between areas. When every door, cover, and panel has its own specification, even routine maintenance becomes unnecessarily complex. Streamlining Operations Through Standardisation By adopting one tamper-resistant locking system across your estate, you immediately simplify how maintenance and security teams operate. With one key system, one specification, and one consistent performance level, Contour Secure helps estates achieve: Operational simplicity: Maintenance teams know exactly how to access, service, and secure enclosures across the estate. Faster response times: Standard locks reduce the need for key changes or component sourcing. Reduced inventory: Only one set of parts and tools is required, cutting procurement and storage costs. Improved accountability: One controlled access system limits unauthorised use and simplifies record keeping. In environments where time and resources are limited, standardisation delivers measurable efficiency gains that quickly offset initial upgrade costs. Efficiency that Enhances Safety Operational efficiency isn’t just about saving time; it’s about improving safety. When maintenance processes are streamlined, teams can respond faster to emerging issues and complete safety-critical repairs without delay. Contour Secure’s tamper-resistant locking system combines efficiency with protection, offering: Flush, anti-ligature design for safety. Durable, wipe-clean surfaces for infection control. Reliable, uniform operation across all fitted products. With one system, every part of the estate works the same way, predictable, manageable, and secure. Proven Value Across Healthcare Estates Standardisation has already proven its value across healthcare environments. Estates teams report: Reduced maintenance workloads thanks to simplified procedures. Improved staff confidence from knowing one consistent standard applies throughout. Lower replacement costs as durable components last longer under consistent specification. In other words, standardisation doesn’t just make estates more compliant, it makes them more sustainable. Conclusion: Streamline for Safety and Savings Inconsistency creates unnecessary complexity. By standardising to Contour Secure’s tamper-resistant locking system, NHS Estates teams can simplify operations, save costs, and strengthen safety, all through one proven platform. Find out how Contour Secure can help you streamline operations and reduce maintenance costs through one simple standardisation programme. 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk

09 December 2025

Secure Locking for IPS Panels: Protecting Critical Services in Healthcare

Behind every healthcare environment is an intricate network of plumbing, mechanical, and electrical services. Much of this is hidden behind IPS (Integrated Plumbing System) panels, a discreet design choice that keeps patient areas clean, safe, and functional. IPS panels, however, are only as secure ...

Behind every healthcare environment is an intricate network of plumbing, mechanical, and electrical services. Much of this is hidden behind IPS (Integrated Plumbing System) panels, a discreet design choice that keeps patient areas clean, safe, and functional. IPS panels, however, are only as secure as the locks that protect them. When outdated mechanisms are specified, the risks multiply: unauthorised access, exposure to live services, compromised infection control, and unnecessary maintenance costs. This blog explores why IPS panel locking matters and how modern cam locks are helping healthcare estates safeguard critical services. Why IPS Panels are Essential IPS panels conceal pipework, valves, and other plumbing components in patient bathrooms, treatment areas, and clinical spaces. Their purpose is twofold: Hygiene and safety: Reducing clutter and making surfaces easier to clean. Access for maintenance: Allowing authorised staff to reach services quickly and safely. As they are present in patient-facing environments, IPS panels must strike a balance between easy access for staff and effective security against tampering. The Risks of Outdated Locks Legacy locking mechanisms, such as pin hex, crown, or square-head designs, are still common on IPS panels. While once considered reliable, they present several challenges in modern healthcare estates: Tampering and forced entry: Basic tools can often be used to open or damage panels. Exposure to live plumbing: Patients may gain access to scalding pipes or other hazards. Hygiene concerns: Recessed lock faces trap dirt, making thorough cleaning difficult. Frequent maintenance: Weak locks often require repeated repairs or replacements. These risks are amplified in mental health or custodial settings, where ligature points or unsecured services can create serious safety issues. The Case for Modern Cam Locks Modern tamper-resistant cam locks are designed to overcome these shortcomings while fitting seamlessly into IPS panel systems. Key benefits include: Tamper-resistance: Three-point engagement mechanisms resist manipulation. Flat-surfaced design: Smooth lock faces support infection control protocols. Low-profile construction: Reduces ligature risks in high-security environments. Visual lock indicators: Allow staff to confirm security immediately. Retrofittable footprint: Enables quick upgrades without replacing entire panels. These features mean IPS panels remain secure, hygienic, and compliant, without adding unnecessary complexity for estates teams. Protecting Critical Services IPS panels may appear ordinary, but they conceal vital infrastructure. By investing in secure locking systems, healthcare providers can: Reduce the risk of unauthorised access. Support compliance with infection control standards. Protect patients from exposure to hidden hazards. Minimise operational downtime caused by breaches or repairs. In an era where estates teams are expected to deliver more with less, improving lock security on IPS panels is a small step with major benefits. Stronger Security for IPS Panels IPS panels are a cornerstone of modern healthcare environments, but without secure locks, they represent a weak point in safety and hygiene strategies. Upgrading to tamper-resistant, flat-surfaced cam locks is a fast, cost-effective way to protect patients, reduce maintenance risks, and safeguard critical services. 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk🌐 Or visit: www.contoursecure.co.uk to request a sample or discuss how secure cam locks can enhance IPS panels across your estate.

04 December 2025

Consistency Equals Compliance: Simplifying Audits and Inspections Through Standardisation

For NHS Estates and Facilities teams, compliance is not optional, it’s a core part of maintaining safe, high-quality care environments. From Health Technical Memoranda (HTM) guidance to CQC inspection requirements, estates must demonstrate that their infrastructure meets strict safety, hygiene, and ...

For NHS Estates and Facilities teams, compliance is not optional, it’s a core part of maintaining safe, high-quality care environments. From Health Technical Memoranda (HTM) guidance to CQC inspection requirements, estates must demonstrate that their infrastructure meets strict safety, hygiene, and operational standards. Yet many estates still face the same challenge: inconsistency. Over time, multiple contractors, reactive maintenance, and varying specifications have created a complex mix of lock types, fittings, and finishes across wards. When auditors or inspectors arrive, these inconsistencies make it harder to prove compliance, even when safety measures are in place. Contour Secure’s Standardisation Programme helps NHS teams address this problem head-on by aligning the estate to one tamper-resistant locking system that’s consistent, compliant, and easy to manage. The Compliance Challenge In mental health settings, inconsistency isn’t just an operational issue, it’s a compliance risk. During inspections, assessors look for evidence of: Secure, tamper-resistant fittings Anti-ligature design principles Consistent hygiene standards Robust maintenance and access control procedures If lock types or access points vary between wards, auditors often need separate justifications or documentation for each product in use. This creates additional workload for Estates teams and can expose gaps where compliance records are incomplete or unclear. How Standardisation Simplifies Compliance Moving to a single locking standard helps eliminate these gaps. With one system consistently applied across all enclosures, from radiator covers and IPS panels to fitted furniture, Estates teams can present a clear, unified safety standard during audits and inspections. Contour Secure’s tamper-resistant locking system is designed to meet the requirements of HTM guidance and CQC inspection criteria, offering peace of mind that each lock across the estate performs to the same proven level of safety and hygiene. The benefits of standardisation for compliance include: Clear documentation: One specification means one compliance record for all relevant fittings. Reduced inspection complexity: Auditors can assess one standard across multiple locations rather than dozens of variations. Consistent performance: A tamper-resistant, anti-ligature design proven across healthcare estates. Simplified maintenance evidence: With standardised locks, maintenance logs and inspection checklists are uniform and easier to update. Supporting Estates and Facilities Teams Contour Secure partners with NHS teams to make compliance straightforward. Through our Standardisation Programme, we: Audit existing enclosures and identify non-compliant or inconsistent fittings. Create a phased upgrade plan to align all enclosures with a single compliant standard. Provide documentation and training to support audit readiness and inspection reporting. This structured approach ensures estates are not only compliant today but remain prepared for future regulatory changes. Beyond Compliance: Confidence and Clarity Compliance isn’t just about meeting external standards, it’s about creating safe, predictable environments for patients, staff, and maintenance teams. By standardising to our tamper-resistant locking system, Estates teams gain control, clarity, and confidence. The system’s design supports easy cleaning, consistent hygiene, and durable security, all key considerations for healthcare inspections. With one standard applied across all wards, compliance moves from being a reactive challenge to a proactive achievement. Conclusion: Make Compliance Simple with Standardisation Standardisation is more than a design decision; it’s a compliance strategy. By aligning to Contour Secure’s tamper-resistant locking system, NHS Estates teams can simplify inspections, strengthen documentation, and maintain consistent safety across all environments. Speak to Contour Secure today about aligning your estate to a single, compliant locking standard and make your next audit simple, confident, and stress-free. 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk

02 December 2025

Eliminating Weak Points: How Standardisation Improves Safety in Mental Health Environments

In safety-critical environments such as mental health facilities, small inconsistencies can have significant consequences. When access panels, radiator covers, or enclosures use different lock types across wards or buildings, these variations introduce weak points that compromise safety. Contour ...

In safety-critical environments such as mental health facilities, small inconsistencies can have significant consequences. When access panels, radiator covers, or enclosures use different lock types across wards or buildings, these variations introduce weak points that compromise safety. Contour Secure’s Standardisation Programme has been developed to help NHS Estates and Facilities teams remove these inconsistencies by transitioning to a single, tamper-resistant locking system. This approach strengthens safety, simplifies maintenance, and builds long-term confidence across estates. The Problem with Mixed Locking Systems Across many NHS sites, legacy locking solutions have developed over time through multiple refurbishments, maintenance cycles, and supplier changes. This often leaves estates with a mix of: Old cam locks that can be forced open or picked using everyday items Triangular key systems that are easily duplicated or misplaced Ad-hoc locks fitted by various contractors, often without a unified specification Each inconsistency increases the chance of unauthorised access, potential ligature points, and gaps in compliance. For mental health environments, where patient safety is paramount, these inconsistencies present unacceptable risk. Creating Consistency for Safer Spaces By adopting one locking standard across the estate, NHS Trusts can eliminate these vulnerabilities. Contour Secure’s tamper-resistant locking system is designed specifically for use in safety-critical environments, offering anti-ligature, flush-fit, and wipe-clean performance. When implemented as part of a structured standardisation programme, the benefits extend well beyond physical safety: Predictability: Every ward and panel follows the same locking specification, removing uncertainty for maintenance and security teams. Fewer keys: A single controlled access system simplifies key management and prevents unauthorised duplication. Reduced risk: Consistent, tamper-resistant locks close the gaps left by legacy or untested solutions. A Proactive Approach to Risk Reduction Safety within mental health environments depends on proactive management, identifying and addressing risks before they cause harm. Standardisation embodies this approach by turning a reactive maintenance challenge into a structured, estate-wide solution. Contour Secure works with estates teams to: Audit existing enclosures to identify where legacy locks are in use. Develop a phased upgrade plan that can be implemented with minimal disruption. Train and support staff, ensuring the new system is used safely and effectively. The result is an environment that is not only safer for patients and staff but also easier to maintain and monitor over time. Safely Designed for Healthcare Our tamper-resistant locking system is designed to be used within the healthcare sector. Every detail, from the flush fit to the smooth surface, supports safety, hygiene, and long-term durability. By bringing consistency to enclosures across mental health settings, Contour Secure helps estates teams align safety objectives with operational efficiency and compliance requirements. Conclusion: Eliminating Weak Points Through Standardisation Inconsistencies create risks. Standardisation removes them. By adopting Contour Secure’s tamper-resistant locking system across your estate, you can eliminate weak points, reduce safety risks, and ensure your environments meet the highest standards of protection. Book a Contour Secure Standardisation Audit today and start eliminating safety risks across your estate. 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk

27 November 2025

Retrofitting Cam Locks: Why Quick Upgrades Reduce Costs and Downtime

Healthcare estates are under constant pressure to balance safety, compliance, and budgets, all while minimising disruption to patient care. One area where this balance can be struck effectively is through retrofitting. Cam locks, though small, are critical components in IPS panels, access hatches, ...

Healthcare estates are under constant pressure to balance safety, compliance, and budgets, all while minimising disruption to patient care. One area where this balance can be struck effectively is through retrofitting. Cam locks, though small, are critical components in IPS panels, access hatches, and healthcare furniture. When they fail, the consequences can include increased maintenance callouts, infection control concerns, and compromised patient safety. However, replacing entire panels or furniture units is expensive and disruptive. Retrofitting with modern cam locks provides a practical, cost-effective way to upgrade security and hygiene without unnecessary downtime. Why Retrofitting Matters Healthcare environments rarely have the luxury of closing wards or patient areas for long upgrades. Estates teams need solutions that are: Fast to install, reducing disruption to patients and staff. Compatible with existing products, avoiding costly replacements. Budget-friendly, providing measurable safety improvements without overspending. This is where modern tamper-resistant cam locks stand out, many are designed to fit the same footprint as legacy locks, allowing quick replacement with no need for drilling or modifications. The Cost of Doing Nothing Ignoring outdated locks can have hidden costs. Legacy pin hex, crown, or square-head designs are more vulnerable to tampering, harder to clean, and prone to damage. Over time, this can lead to: Frequent maintenance callouts, stretching resources. Costly replacements of entire panels or furniture units. Infection control risks where recessed or dirt-trapping designs make cleaning difficult. Extended downtime when patient areas need to be taken offline for repairs. These issues add up both financially and operationally. The Benefits of Retrofitting Modern Locks Switching to tamper-resistant cam locks brings clear advantages: Cost savings: Replace only the lock, not the entire enclosure or unit. Minimal downtime: Retrofits are quick and easy, meaning wards remain operational. Improved hygiene: Flat-surfaced designs support infection control protocols. Enhanced safety: Low-profile, tamper-resistant mechanisms reduce risks. Futureproofing: Modern locks are designed with today’s healthcare standards in mind, giving facilities more resilience. For estates teams under pressure, retrofitting provides an efficient way to improve safety standards while protecting budgets. Real-world Impact Consider the difference between two scenarios: Replacing an entire IPS panel due to weak locks could cost hundreds in materials and labour, plus downtime. Retrofitting with a modern cam lock can be achieved at a fraction of the cost and with minimal disruption. The long-term impact is just as significant: fewer callouts, fewer replacements, and greater confidence in patient safety. Retrofitting Made Simple When it comes to healthcare estates, retrofitting cam locks is one of the fastest, most cost-effective ways to improve safety and hygiene. With designs that fit standard footprints, upgrading is simple, and the benefits are immediate. Why replace entire panels or furniture units when a smarter upgrade exists? 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk🌐 Or visit: www.contoursecure.co.uk to request a sample or discuss how retrofitting cam locks can reduce costs and downtime in your estate.

25 November 2025

From Bathrooms to Bedrooms: Secure Locking Across Healthcare Estates

Healthcare estates are made up of diverse environments, from high-traffic corridors to private patient bedrooms. Each of these areas has different requirements, but all share the same need for secure, hygienic, and tamper-resistant locking systems. Cam locks may seem small, but their presence ...

Healthcare estates are made up of diverse environments, from high-traffic corridors to private patient bedrooms. Each of these areas has different requirements, but all share the same need for secure, hygienic, and tamper-resistant locking systems. Cam locks may seem small, but their presence across bathrooms, bedrooms, and beyond means they play a vital role in maintaining safety, supporting infection control, and protecting staff, patients, and visitors alike. This blog explores the varied applications of locks across healthcare estates and highlights why choosing the right design is essential for modern facilities. Bathrooms: Balancing Safety and Hygiene Bathrooms in healthcare settings are complex environments. IPS panels conceal essential plumbing, while access hatches allow maintenance teams to service water systems. When secured with outdated locks however, these points can present real risks: Tampering or forced access to concealed services. Exposure to hot water pipes, with potential for scalding. Hygiene challenges, as recessed locks trap dirt and bacteria in areas requiring high cleaning standards. Modern flat-surfaced, tamper-resistant cam locks support both infection control and patient safety, helping teams maintain clean, secure bathrooms. Bedrooms: Protecting Privacy and Safety In bedrooms and ward areas, furniture and built-in storage units are commonly fitted with locks. While designed to support staff, they can create unintended risks if poorly specified: Protruding locks create ligature points in mental health environments. Weak mechanisms invite tampering or damage. Unhygienic surfaces can undermine infection prevention protocols. Upgrading to low-profile, flat-surfaced cam locks helps reduce ligature risks, improve hygiene, and maintain patient privacy without introducing unnecessary hazards. Corridors and Communal Spaces: Overlooked Access Points Corridors and communal spaces often feature access hatches and panels for electrical and mechanical services. These points are vital for estates teams but, when fitted with legacy locks, they can be easy targets for tampering. Modern tamper-resistant locks reduce opportunities for unauthorised access while providing staff with efficient, reliable mechanisms for daily use. Their discreet appearance also helps maintain a non-institutional environment, especially important in patient-facing areas. Why Consistency Matters Across bathrooms, bedrooms, and corridors, one theme is clear: consistency matters. When estates adopt modern cam locks across the entire facility, the benefits multiply: Improved safety, with fewer weak points vulnerable to tampering. Streamlined cleaning, with smooth, wipe-clean lock faces across all applications. Simplified maintenance, as standardised locking systems reduce confusion and improve efficiency. Cost-effective retrofits, as many tamper-resistant cam locks can be fitted into the same footprint as standard designs. One Locking Standard for Every Space Furniture locks may seem insignificant compared to doors or IPS panels, but when they harbour bacteria or fail to secure sensitive items, their impact is felt across the healthcare environment. For estates managers, infection control leads, and product manufacturers, the message is clear: locks aren’t just hardware, they’re part of the wider safety and hygiene strategy. 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk🌐 Or visit: www.contoursecure.co.uk to request a sample or discuss how secure cam locks can support safer healthcare estates.

21 November 2025

The Hidden Hygiene Risks in Healthcare Furniture Locks

When we think of infection control in healthcare, the focus often falls on high-touch surfaces like door handles, bed rails, and clinical worktops. One area that frequently escapes attention is furniture locks. From storage cupboards in wards to cabinets in treatment rooms, furniture plays a ...

When we think of infection control in healthcare, the focus often falls on high-touch surfaces like door handles, bed rails, and clinical worktops. One area that frequently escapes attention is furniture locks. From storage cupboards in wards to cabinets in treatment rooms, furniture plays a central role in day-to-day healthcare operations, and so do the locks that secure it. Yet, many of these locks are not designed with hygiene in mind, creating hidden risks that can undermine infection control efforts. This blog explores where hygiene issues arise, the impact of poor lock design, and how modern cam locks are helping healthcare environments raise their standards. Why Furniture Locks Matter Healthcare furniture is used daily by staff across wards, theatres, and treatment areas. Cabinets secure medications, equipment, and supplies, while storage units keep clinical spaces uncluttered and safe. As these items are in constant use, their locks are frequently touched, often by multiple people during a single shift. Without the right design, furniture locks can quickly become a weak link in hygiene protocols. The Hygiene Risks of Legacy Lock Designs Many traditional locks used in healthcare furniture are not created with infection control in mind. Common risks include: Recessed keyways and cavities that trap dust, dirt, and pathogens, making thorough cleaning difficult. Multiple grooves and ridges around the lock face, creating more surface area for bacteria to cling to. Institutional bulkiness, with protruding faces that collect dirt and can interfere with cleaning equipment. Infrequent cleaning, as staff may not consider locks a priority in hygiene routines due to their fiddly or recessed design. In an environment where every detail contributes to infection control, these issues can’t be ignored. The Benefits of Flat-surfaced Lock Design Modern cam locks address these challenges with flat-surfaced, smooth designs that support infection control practices. By eliminating recesses and sharp edges, these locks reduce the areas where dirt and bacteria can accumulate. The advantages include: Easier cleaning routines, with simple wipe-down surfaces that fit seamlessly into regular disinfection protocols. Reduced risk of bacterial build-up, as there are fewer areas for pathogens to hide. Better compatibility with anti-microbial coatings, which can be applied more effectively to smooth surfaces. Visual reassurance, with a sleek, hygienic appearance that aligns with modern healthcare design. More Than Just Hygiene: Safety and Efficiency While hygiene is a major driver, flat-surfaced cam locks also bring other benefits in healthcare settings: Tamper resistance, helping prevent unauthorised access to cabinets and storage. Ligature-resistant design, reducing risks in mental health or custodial healthcare environments. Ease of retrofitting, allowing existing furniture to be upgraded without costly replacements. Operational efficiency, with clear lock indicators and smooth mechanisms that save time during busy shifts. These factors make modern cam locks a versatile solution that addresses multiple priorities at once. The Overlooked Weak Point Furniture locks may seem insignificant compared to doors or IPS panels, but when they harbour bacteria or fail to secure sensitive items, their impact is felt across the healthcare environment. For estates managers, infection control leads, and product manufacturers, the message is clear: locks aren’t just hardware, they’re part of the wider safety and hygiene strategy. Upgrade Hygiene Where it Matters Most Furniture locks are touched daily but rarely considered in infection control planning. Outdated designs can trap dirt, harbour bacteria, and undermine hygiene protocols. By switching to flat-surfaced, tamper-resistant cam locks, healthcare estates and manufacturers can make cleaning easier, improve patient safety, and extend the usability of existing furniture. 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk🌐 Or visit: www.contoursecure.co.uk to request a sample or discuss how hygienic cam locks can support safer healthcare environments.

14 November 2025

IPS and Access Panels: Why Secure Locks Matter in Patient-facing Areas

In healthcare design, many elements are carefully considered, from ventilation systems to hygiene finishes. One area however is often overlooked being the locking of IPS (Integrated Plumbing System) and access panels. These panels are everywhere in healthcare estates: in patient bathrooms, ward ...

In healthcare design, many elements are carefully considered, from ventilation systems to hygiene finishes. One area however is often overlooked being the locking of IPS (Integrated Plumbing System) and access panels. These panels are everywhere in healthcare estates: in patient bathrooms, ward corridors, clinical spaces, and staff areas. They may look like minor components, but when the locks securing them fail, the risks can be significant. This blog examines why IPS and access panels require more than standard locks, what risks arise from legacy designs, and how modern tamper-resistant cam locks are supporting safer, more resilient healthcare environments. Why IPS and Access Panels are Critical IPS panels provide access to concealed plumbing and services, keeping healthcare spaces clean, safe, and easy to maintain. Access panels allow authorised staff to reach electrical, mechanical, and network infrastructure across wards and corridors. Both are essential for day-to-day operations, but their placement in patient-facing areas also means they are exposed to risks, including: Tampering and forced entry by patients or visitors. Exposure to live services, creating potential safety hazards. Hygiene concerns, as recessed locks and handles trap dirt or bacteria. Visual disruption, where bulky or institutional lock designs undermine therapeutic environments. A compromised panel isn’t just a minor inconvenience, it can pose serious risks to safety, infection control, and the overall quality of care. The Risks of Legacy Locking Solutions Many IPS and access panels are still fitted with legacy cam locks such as: Pin hex and crown locks, once considered secure but now easily bypassed with basic tools. Square head and tri-head inserts, standard across commercial buildings but not designed for patient-accessible areas. These locks can often be forced open, introducing avoidable risks. In healthcare environments where patient welfare and infection control are critical, relying on outdated locking mechanisms leaves facilities exposed. How Modern Cam Locks Make a Difference Modern tamper-resistant cam locks are designed with healthcare-specific challenges in mind. Their features provide a more robust approach to panel security: Three-point engagement mechanisms reduce the risk of manipulation. Smooth, flat-surfaced faces simplify cleaning and help meet infection control standards. Low-profile, ligature-resistant designs minimise hazards in mental health or custodial healthcare settings. Visual engagement indicators allow staff to confirm straight away that panels are properly secured. Retrofittable footprints make upgrading straightforward, with no need for expensive modifications. By upgrading locks, estates teams can protect panels from tampering, improve hygiene, and extend the lifespan of existing infrastructure. Supporting Safer Healthcare Environments Access to plumbing and electrical systems will always be necessary in healthcare estates, but access should be controlled, safe, and secure. By specifying or retrofitting tamper-resistant cam locks on IPS and access panels, healthcare providers can: Reduce risks of unauthorised access. Support infection control protocols. Maintain the therapeutic design of patient areas. Minimise downtime and reduce costly repairs. Small changes at the component level can make a significant difference across entire estates. Secure the Access Points that Matter Most IPS and access panels may be small parts of a healthcare environment, but the risks of inadequate locks are anything but small. From patient safety to infection control, choosing the right lock makes a measurable impact. Whether you’re upgrading existing panels or specifying new builds, modern tamper-resistant cam locks provide a fast, cost-effective way to improve security and resilience. 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk🌐 Or visit: www.contoursecure.co.uk to request a sample or discuss how secure locks can support safer healthcare estates.

07 November 2025

Cam Locks in Healthcare: Small Components, Big Impact on Safety

In healthcare environments, safety and security are often thought of in terms of buildings, wards, and major systems. Yet, some of the most important safeguards come down to the smallest components, including the locks that secure access points, panels, and equipment. Cam locks, while compact, play ...

In healthcare environments, safety and security are often thought of in terms of buildings, wards, and major systems. Yet, some of the most important safeguards come down to the smallest components, including the locks that secure access points, panels, and equipment. Cam locks, while compact, play an outsized role in healthcare estates. From IPS panels in washrooms to access hatches in corridors, furniture in patient areas, and specialist equipment enclosures, these locks influence not only the integrity of infrastructure but also the safety and experience of staff and patients. This blog explores how cam locks contribute to safety, where they’re most used, and why choosing the right design is critical. The Overlooked Role of Cam Locks in Healthcare Too often, locks are treated as an afterthought in product and facility design. Standard options, like pin hex or square-head inserts, are still widely used despite their vulnerabilities. In healthcare settings, the risks of outdated or inadequate locks include: Unauthorised access: Patients or visitors forcing entry into panels or cabinets. Tampering with equipment: Compromising electrical, medical, or plumbing systems. Hygiene concerns: Recessed or multi-part lock faces that trap dirt and bacteria. Ligature risks: Protruding lock mechanisms that introduce hazards in mental health or custodial environments. A lock might be small, but its impact extends far beyond its footprint. Where Cam Locks Matter Most Cam locks appear in a wide range of healthcare applications. Some of the most common include: IPS panels: Providing access to plumbing and essential services in patient and staff washrooms. Access panels and hatches: Found across wards, corridors, and plant rooms. Healthcare furniture: From storage units to cabinets, locks protect against tampering and maintain safety. Specialised enclosures: Cabinets for electrical or mechanical systems, often in publicly accessible areas. Each of these applications presents different challenges, but the principles remain the same: locks must be tamper-resistant, hygienic, and easy for authorised staff to use. The Benefits of Modern Cam Lock Design Today’s tamper-resistant cam locks are designed with these demands in mind. Features that make a difference include: Three-point engagement mechanisms that reduce the risk of manipulation. Smooth, flat-surfaced faces that are easier to clean and less prone to dirt build-up. Low-profile, ligature-resistant designs that minimise protrusions and potential risks. Visual indicators to show immediately whether a panel is locked or open. Retrofittable footprints that allow easy replacement of legacy locks without expensive modifications. These innovations allow estates teams and manufacturers to address multiple priorities at once - security, hygiene, safety, and efficiency. Why Small Components Make a Big Impact It’s easy to underestimate cam locks, but their importance becomes clear when things go wrong. A compromised access panel can expose live services, a poorly cleaned lock can undermine infection control protocols, and a ligature risk can have life-threatening consequences. By upgrading to modern cam lock designs, healthcare estates can improve security, reduce risks, and extend the usable life of existing infrastructure. For manufacturers, these locks provide a way to align with the latest NHS and private healthcare specifications, without introducing complex or costly design changes. Small Upgrades, Safer Spaces In healthcare, no detail is too small when it comes to safety. Cam locks may be compact, but their influence on hygiene, tamper-resistance, and patient safety is significant. Whether you’re retrofitting existing estates or specifying products for new builds, choosing purpose-designed cam locks can deliver measurable improvements in safety and efficiency. 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk🌐 Or visit: www.contoursecure.co.uk to request a sample or discuss how cam locks can support safer healthcare environments.

30 October 2025

Healthcare Estates 2025: What Locking Innovations Mean for Safer Environments

The Healthcare Estates exhibition is always a key moment in the calendar for anyone involved in designing, managing, and supplying safe healthcare facilities. The 2025 event, held at Manchester Central, brought together estates teams, designers, specifiers, and product manufacturers to explore the ...

The Healthcare Estates exhibition is always a key moment in the calendar for anyone involved in designing, managing, and supplying safe healthcare facilities. The 2025 event, held at Manchester Central, brought together estates teams, designers, specifiers, and product manufacturers to explore the theme “Prevention is Better than Cure.” While much of the focus was on buildings, energy systems, and digital health solutions, there was a clear thread running through the conversations: the importance of small details in delivering safe, reliable, and cost-effective healthcare environments. Among those details, locking mechanisms took centre stage in a way they rarely have before. This blog reflects on the innovations showcased at Healthcare Estates 2025, highlights the growing importance of locking hardware in healthcare design, and looks ahead to what estates teams can expect next. Why Locking Solutions are Now in the Spotlight Traditionally, locks have been treated as routine hardware, chosen quickly from standard catalogues with little consideration for the unique demands of healthcare. But in 2025, conversations made clear that approach is no longer enough. Healthcare environments face specific challenges that set them apart from other sectors: Tampering and security risks in patient-accessible areas, from IPS panels to access hatches. Infection control requirements that demand smooth, wipe-clean finishes on all hardware. Safety expectations in mental health and custodial healthcare settings, where ligature resistance is essential. Cost and downtime pressures that require solutions to be easy to install, retrofit, and maintain. The message from this year’s event was simple: the humble lock can no longer be overlooked. Key Innovations Highlighted at Healthcare Estates 2025 Flat-surfaced, hygienic lock designsLocks with recessed inserts and crevices were a recurring concern. New flat-surfaced locks designed for wipe-clean maintenance were widely discussed as a step forward for infection prevention strategies. Tamper-resistant mechanismsLocks designed to reduce the opportunities for manipulation with everyday tools are increasingly being prioritised, especially for products located in patient-facing or publicly accessible areas. Retrofittable solutionsWith budgets tight, estates teams are prioritising upgrades that can be delivered quickly and affordably. Locks designed to fit the same footprint as traditional cam locks offer a way to strengthen security without replacing panels or furniture. Visual engagement indicatorsAt-a-glance security checks, showing whether a lock is engaged or disengaged, are gaining interest as estates teams look to improve efficiency and reduce human error during inspections. Looking Ahead: Future Trends for Locking in Healthcare The 2025 show didn’t just highlight the present, it set the stage for what’s next. Some of the key trends to watch include: Standardisation of tamper-resistant locks in NHS procurement frameworks, as awareness grows of the risks posed by legacy designs. Integration with broader infection control strategies, where every component, including hardware, is scrutinised for hygiene performance. Greater emphasis on retrofit programmes, as hospitals look to extend the life of existing estates without compromising safety. Expansion of ligature-resistant locking solutions, reflecting the crossover between general healthcare and secure mental health environments. As healthcare estates evolve, locking mechanisms will increasingly be seen as frontline components of safety, not just background hardware. Small Components, Big Difference Healthcare Estates 2025 reinforced an important point: in secure healthcare design, even the smallest details matter. Locks may be simple in form, but they play a critical role in hygiene, patient safety, and operational resilience. Whether you’re designing new facilities or managing existing estates, locking mechanisms deserve the same attention as any other safety-critical component. Retrofittable, tamper-resistant, and hygienic locks are already shaping the future of safer healthcare environments. 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk🌐 Or visit: www.contoursecure.co.uk to request a sample or discuss how locking innovations could strengthen your next project.

24 October 2025

Retrofitting in Healthcare: A Fast, Cost-effective Upgrade for Safer Facilities

Healthcare estates are under constant pressure. Budgets are tight, patient safety expectations are rising, and facilities teams must deliver secure, hygienic environments without disrupting day-to-day care. For many, the question is simple: how do you improve safety and compliance without replacing ...

Healthcare estates are under constant pressure. Budgets are tight, patient safety expectations are rising, and facilities teams must deliver secure, hygienic environments without disrupting day-to-day care. For many, the question is simple: how do you improve safety and compliance without replacing entire systems or investing in major refurbishments? The answer is retrofitting. Retrofitting locks provides a fast, cost-effective way to improve safety across healthcare environments. Instead of replacing entire IPS panels, access panels, or furniture units, facilities teams can upgrade the locking mechanisms alone, turning existing infrastructure into safer, more hygienic, and tamper-resistant solutions. This blog explores why retrofitting is gaining momentum, how it benefits healthcare facilities, and why locks are one of the easiest and most impactful upgrades to make. Why Retrofitting Makes Sense in Healthcare Healthcare estates are complex. From acute mental health units to general hospitals, facilities often contain a mix of old and new infrastructure. Replacing entire systems when security or hygiene issues arise can be prohibitively expensive and disruptive. Retrofitting addresses these challenges by offering: Cost savings: Upgrading locks is a fraction of the cost of replacing panels or furniture. Minimal disruption: Retrofitting avoids demolition or major alterations, meaning wards and corridors can stay operational. Flexibility: Modern locks can fit into the same footprint as standard cam locks, making upgrades simple. Faster installation: Estates teams or contractors can complete upgrades quickly, reducing downtime. With healthcare budgets under strain, retrofitting offers a practical way to extend the lifespan of existing assets while raising safety standards. Common Challenges with Legacy Locks Traditional lock designs create unnecessary risks in healthcare environments. Among the most common problems are: Tampering risks: Pin hex and other legacy locks can be bypassed with basic tools. Infection control: Recessed lock inserts trap bacteria and are almost impossible to clean effectively. Maintenance costs: Worn or damaged locks increase callouts and replacements. Ligature risks: Protruding or poorly finished lock faces can pose dangers in secure healthcare settings. These issues compromise both patient safety and the operational efficiency of estates teams. Retrofitting with tamper-resistant, flat-surfaced locks addresses these risks at the source. How Retrofitting Works in Practice One of the key strengths of modern tamper-resistant cam locks is their retrofittable design. Built to match the same footprint as standard cam locks, they can be slotted into place without costly modifications. Examples include: IPS panels in patient areas: Upgrading recessed locks to flat-surfaced alternatives supports infection control. Access panels in corridors and treatment rooms: Retrofitting prevents tampering and reduces callouts. Furniture locks in bedrooms or staff areas: Modern locks improve safety without requiring new furniture units. For estates teams managing large facilities, retrofitting provides a quick, scalable way to improve security and hygiene across multiple applications. The Benefits for Healthcare Facilities Immediate safety improvementsRetrofitting removes obvious risks like tampering, ligature points, and hard-to-clean surfaces. Cost-effective upgradesInstead of replacing panels or furniture, facilities can upgrade locks alone, saving thousands. Minimal disruption to careWith no demolition or major works required, wards remain operational while upgrades are carried out. Extended lifespan of assetsBy improving the weakest component, facilities can keep existing infrastructure in service longer. Confidence in complianceModern tamper-resistant locks align with updated guidance and procurement requirements for healthcare settings. Upgrade Without the Overheads Retrofitting locks is one of the simplest, fastest, and most cost-effective ways to raise safety standards in healthcare estates. It avoids the expense and disruption of full replacements while giving staff, patients, and estates teams greater confidence in hygiene and security. If your facility still relies on outdated locks, it’s time to take a fresh look. Retrofitting modern, tamper-resistant cam locks turns existing infrastructure into safer, more resilient assets. 📞 Call us: 01952 890158📧 Email: sales@contoursecure.co.uk🌐 Or visit: www.contoursecure.co.uk to request a sample or discuss how retrofitting could strengthen your facility.

14 October 2025

Designing for Hygiene: The Role of Flat-surfaced Locks in Healthcare

Infection prevention is one of the most pressing challenges for healthcare estates. Every material, surface, and fixture needs to support strict hygiene standards to reduce cross-contamination and protect both patients and staff. While flooring, wall finishes, and clinical equipment often get ...